The Mechanical Engineering Department Welcomes Its First Ever 3D Metal Printer and the Opportunities it Presents

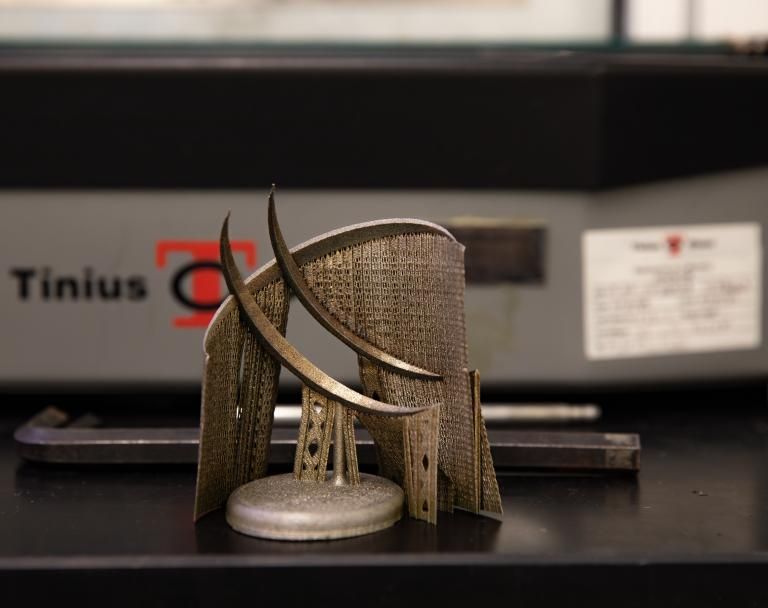

Thanks to the generosity of the Huber Foundation, York College is proud to unveil its brand new 3D metal printer as it continues to undergo testing.

York College of Pennsylvania’s Kinsley Engineering Center is excited to announce that the Mechanical Engineering Department has received its very first 3D metal printer, a machine that is already stirring up interest and ideas for potential projects.

Professors within the department, the most vocal of which was Stephen “Drew” Wilkerson, Ph.D., P.E., Associate Professor of Mechanical Engineering, knew that 3D printing would be the future of printing. Now that they have their own, the opportunity to share the machine with their students and the community has opened many doors for advanced projects and collaborations.

“This is not my field of specialty,” Dr. Wilkerson said, “but I knew this would be a good thing for the school to have in addition to our other 3D printers, which we have quite a few of.”

Building Up a Printer

A gift from the Huber Foundation, the printer was ordered from Xact Metal, a spinoff company from Penn State University. The device was shipped to York College in the early summer 2024 but wasn’t operational until early October 2024.

This was mainly due to a large number of safety equipment and devices they needed, such as a special fire extinguisher and gas masks, Nitrogen, and rubber gloves. Although capable of great things, the 3D metal printer needed to be handled with the proper preventive measures, such as sealing the unit and removing all air from it while ensuring none of the printing powder makes contact with skin.

As for how it works, the 3D metal printer takes a small amount of metal powder and spreads one thin layer over another, heating them up with a high-powered laser and forcing them to melt and fuse with the layer below them. This process is repeated until the desired item or part is printed.

This specific model, the XM200G, is known for its speed and high-quality when it comes to printing. It was one of several items that the Huber Foundation, an organization focused on providing support to the College’s Engineering and Chemistry Departments, helped purchase, all of which were greatly appreciated and have already begun stoking excitement for both students and staff.

Currently, the printer is still in the testing phase, as the professors are continuing to experiment with printing different types of parts and pieces to see what works best. So far, they have found success with fine printing and show pieces, especially for parts that are typically “hard to machine.” Even fidget spinners have been created as part of the experimental process.

Student and Community Collaboration

After years of advocating for a 3D metal printer for the Mechanical Engineering Department, Dr. Wilkerson can’t wait to begin sharing the machine with others.

His hope is that eventually, once the staff has had a chance to better understand the printer and how it works, students will have the opportunity to work with it as well.

“I’m hoping that there will be a student that takes an interest in it for a project,” Dr. Wilkerson said. “We’ll teach them how to use the software, teach them how to set it up and do various things with it, and then they’ll make some projects.”

Ideally, Dr. Wilkerson would like to see a few independent study students work with the printer at first, and as the experience grows, eventually, an entire class will be permitted to come in and use it as a part of a project.

He also wishes to share the experience with York College industry partners, such as Lehr Labs, a 3D printing company run by York College graduates Evan Lehr ’21 and Marcos Rivera ’20. The company, which had expanded into the J.D. Brown Center for Entrepreneurship in Knowledge Park, 3D prints high-quality, customer-requested parts, and now that the College has a metal printer, they will be doing more work in the area with the professors and students at York College.

If the collaboration yields a positive outcome, Lehr expressed even wanting to train and potentially hire students to work part-time with the machine and Lehr Labs.

“One of the things that our school offers,” Dr. Wilkerson said, “that other schools do not, is our students actually get to use the equipment that we have. And we’re really proud that our students, when they come out of the school, can use these pieces of equipment. And in Evan [Lehr]’s case, started his own business based on his own positive experiences with 3D printing.”

Fostering real-world skills and providing opportunities for hands-on experience are vital parts of York College’s student education. Having the right tools can make all the difference in how a student learns and chooses to pursue their interests. Now that the engineering departments are equipped with their first 3D metal printer, Dr. Wilkerson and the other professors are confident of the many ways it will enhance their learning experiences and prepare them for the industry they will eventually work in.