York College ASCE Student Engineering Team Wins First Place in 3D Printing Competition

A group of mechanical engineering students joined the ASCE team to compete in the 2025 ASCE Mid-Atlantic Student Symposium. Thanks to their efforts in the 3D printing competition, they won the first-ever York College first-place win.

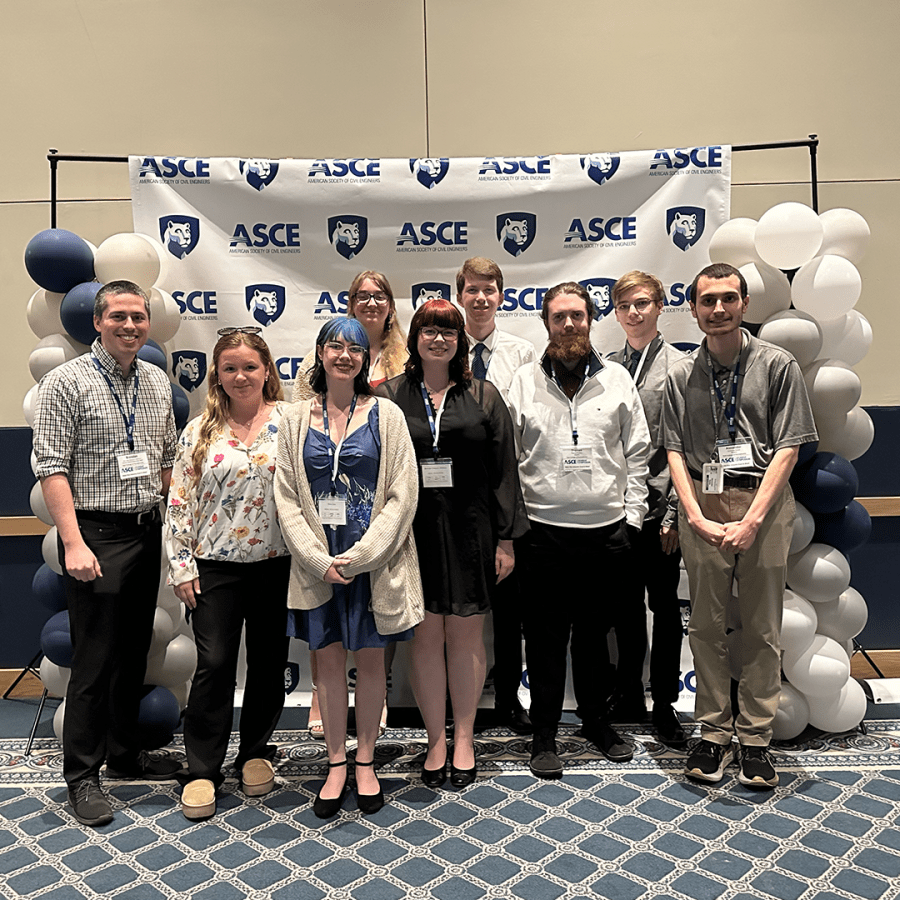

On March 27-29, 2025, Dr. Brendan Grayson-Wallace, Assistant Professor of Civil Engineering, escorted 11 engineering students to the annual ASCE (American Society of Civil Engineers) Mid-Atlantic Student Symposium. There, colleges send members of their ASCE student chapters to compete in a series of competitions that utilize their civil engineering knowledge and skills.

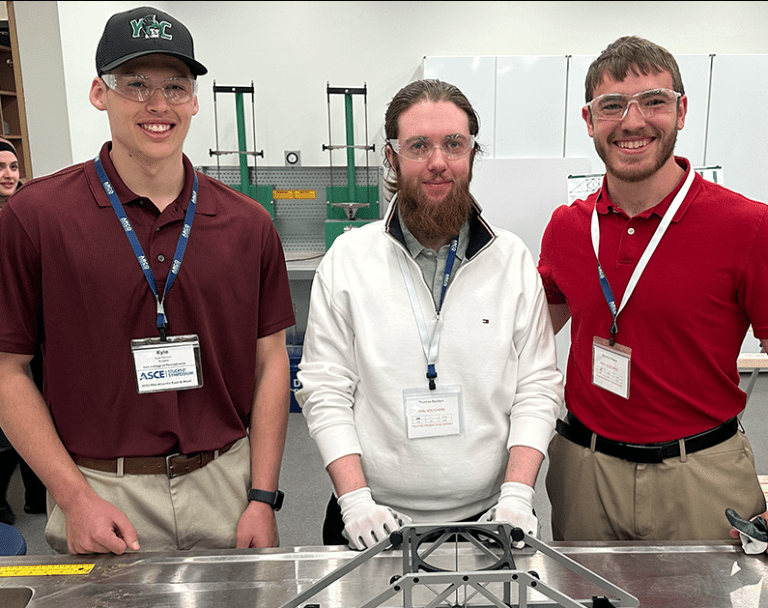

This year, however, York College of Pennsylvania didn’t just bring their Civil Engineering majors; three Mechanical Engineering majors joined them to help their team participate in the ASCE 3D Printing Competition.

The challenge? Build a 3D-printed bridge.

And for the first time in York College history, the College’s ASCE team scored first place in one of the events.

The Challenge

The ASCE Mid-Atlantic Student Symposium holds several civil engineering challenges that test engineers’ skills, ranging from designing to building. Some of the more popular ones include the Concrete Canoe Competition, the Steel Bridge Competition, the UESI Surveying Competition, and the Student Symposium Paper Competition.

Amongst these events, the 3D Printing Competition is one of the newest pilot competitions added to the lineup.

“Over the years, [the ASCE has] been looking for other competitions to broaden the focus of these events,” Dr. Grayson-Wallace said, “because the ASCE Student Symposiums are large events with lots of industry reps that come…There’s a lot of recruiting opportunities, and they wanted to broaden the umbrella of what was included, and so 3D printing became one of those pilot competitions two years ago.”

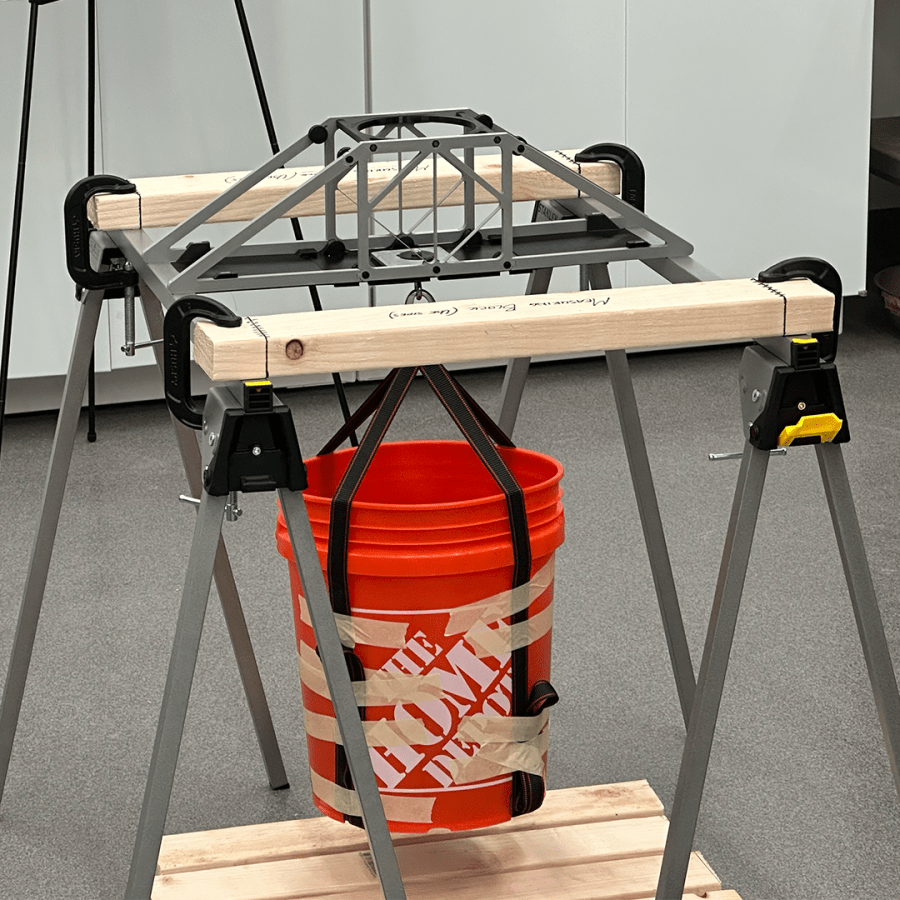

The 3D Printing Competition tasks students with designing, modeling, and printing a small bridge made of PLA plastic. The bridge must be 24 inches long x 6 inches wide x 8 inches tall and be able to hold exactly 70 pounds while weighing no more than 2.2 pounds.

On the competition day, the students presented their bridge designs to the judges (complete with a poster and five-minute presentation), assembled it under timed construction (with faster times scoring better), and then had it load tested while measuring how much it displaced vertically (essentially, how much the bridge sags in the middle).

The York College team began designing its bridge in January. They created several prototypes that they printed and load tested, aiming for a design that wouldn’t be too stiff or too light and flexible to keep it from breaking under the weight.

The three mechanical engineering students were incredible assets during this process, offering their expertise in what to do and what not to do when designing a bridge.

“It’s not as uncommon as you might think, actually,” Dr. Grayson-Wallace said. “Especially the more structure-oriented competitions tend to attract mechanical engineering students as well.”

In the end, the final bridge design weighed around 0.87 pounds and had a deflection of 0.6 millimeters (less than 1/32nd of an inch) at the target load of 25 pounds. The team’s bridge won first place in several of the individual categories, and with its total score, it won first place overall—a first in York College ASCE competition history.

Thinking Outside the Box

So what set York College’s team bridge apart from the competition?

One advantage the team had was their experience with 3D printing. Tommy Redfern ‘27, one of the team’s Mechanical Engineering majors, had a strong background in the subject. He even designed his own hypothetical, full-sized pedestrian bridge as his final project for his Statics class.

Not only did the assignment give Tommy insight into how to build a stable bridge, but it also allowed him and his team members to think about the challenge in a different way.

“Our thinking was, this competition [had] strictly one point load at the center of the bridge,” Tommy said. “On an actual bridge going over a river, there’s a lot more forces that are being considered than just one. There’s trucks going all the way across, there’s wind, there’s resonance in the whole structure.”

Many of the other teams replicated their bridge after existing ones. Realizing that they didn’t need to worry about other outside factors that would typically affect traditional bridge structures, Tommy and the others decided to be a bit more creative and do a unique design, focusing on only one task.

“So, we didn’t have to worry about any of that; we just had to worry about the one point load in the middle,” Tommy said.

Other Stories of Success

The York College team didn’t just have success in the 3D printing competition; they also scored well in the three other competitions they participated in:

- Sustainable Solutions Competition - Fourth Place

- Student Symposium Paper Competition - Third Place

- UESI Surveying Competition - Second Place

Along with the 3D printing team's win, the survey team’s placement was also considered a grand accomplishment, especially considering that this isn’t the first time they have placed so high.

“Last year, our survey team took second again, which is not to be understated,” Dr. Grayson-Wallace said. “The survey competition is a more well-established competition with substantially more schools competing in it.”

Due to the relatively new nature of the 3D printing competition, only six teams competed. The survey competition typically had about 9-12 teams out of the over 20 schools participating in the entire event (with the biggest turnouts being for the concrete canoe and steel bridge competitions).

Taking second place two years in a row was considered a very impressive achievement, Grayson-Wallace explained, because some of the bigger schools bring multiple teams to the competition or ones made up exclusively of upperclassmen. Many of the students on the York College team were either sophomores or juniors, so the fact that they scored so high is a testament to their dedication to honing their skills for the competition.

Finding Joy and Opportunity

There are many benefits for students participating in the symposium, especially when networking with professionals within the civil engineering industry. But many students often enjoy applying what they have learned in the classroom to real-life situations.

“It was fun applying what we’ve been learning in classes,” Tommy said. “I call this kind of like real engineering, you know - doing a bunch of math, to form some design, and so that was interesting to do.”

Seeing the students succeed while enjoying their work was also a wonderful experience for Dr. Grayson-Wallace. Especially given that he was once in their shoes, competing in the ASCE competitions.

“I did Steel Bridge many moons ago when I was a student, and it’s really motivating to take stuff in the classroom and actually build something physical using the math you just learned,” he said. “It’s very satisfying.”

The competition also allows students to add more diverse experiences to their resumes. Employers like to see candidates with experience doing engineering projects, so students being able to talk about the work they have completed during their undergraduate years can be a great way of getting their foot in the door.

“Being a student, having an experience with something as open-ended and as complicated as a competition like this, being able to talk about a project like this in an interview goes a long way of proving that you know what you’re doing to future or prospective employers,” Dr. Grayson-Wallace said.

“Having competitions like this on a resume go a long way, I think, both on paper and in person. They help a lot to have something like this under your belt.”

The ASCE student team is always looking for new members to join them at the symposium, so if you or someone you know is interested in joining, don’t hesitate to take that chance and work with an amazing team on innovative projects.